iNDUSTRIES

Consumer Electronics

As electronics sizes shrink and their complexity grows, processing systems must be able to keep up.

As electronics sizes shrink and their complexity grows, processing systems must be able to keep up.

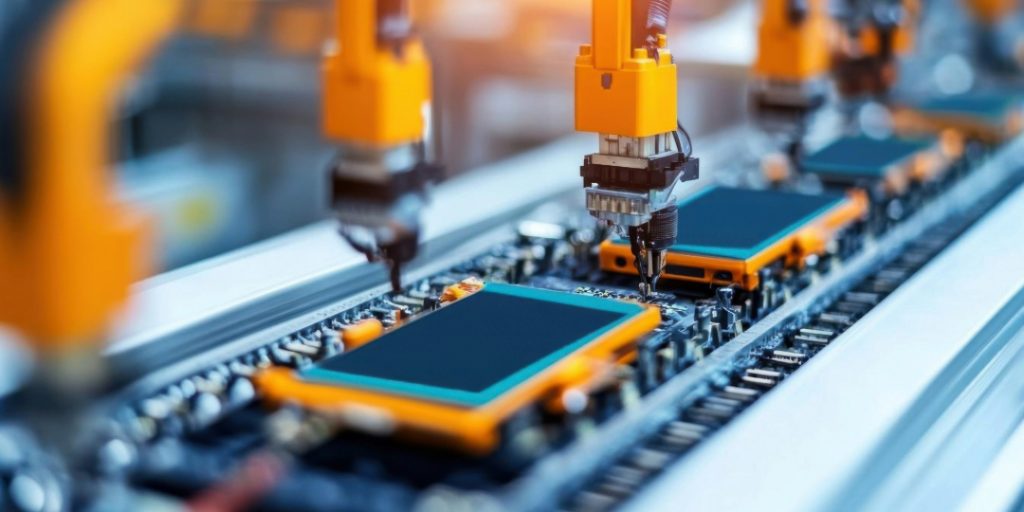

Todays modern individuals, businesses and homes simply cannot function without a wide range of electronic devices. Virtually every consumer product has some form of circuit board inside, many of which are routinely processed by laser drilling and resistor trimming systems. These products range from coffee makers through to smart televisions and phones. PCB types vary based on the size and shape of device ranging from miniature flex circuits in smart watches to larger rigid boards in 85” televisions. Many modern electronics also require substrates with higher thermal conductivity so heat from fast computer processors or high-intensity LEDs can be dissipated.

High density interconnect multi-layer PCBs are built around the concept of miniaturization based on the ever decreasing size of consumer electronics. Board space and cost is being reduced at the same time as the complexity and volume of components is increasing. Creating microvias, both buried and on the surface of a multi-layer PCB is typical, and as their size decreases laser processing systems are required to meet the precision and feature sizes of next generation designs.

PPI’s lineup of ProVia laser drilling models provides a range of application-specific high volume drilling and cutting solutions for rapidly evolving consumer electronics market, delivering industry-leading throughput and lowest cost of ownership.

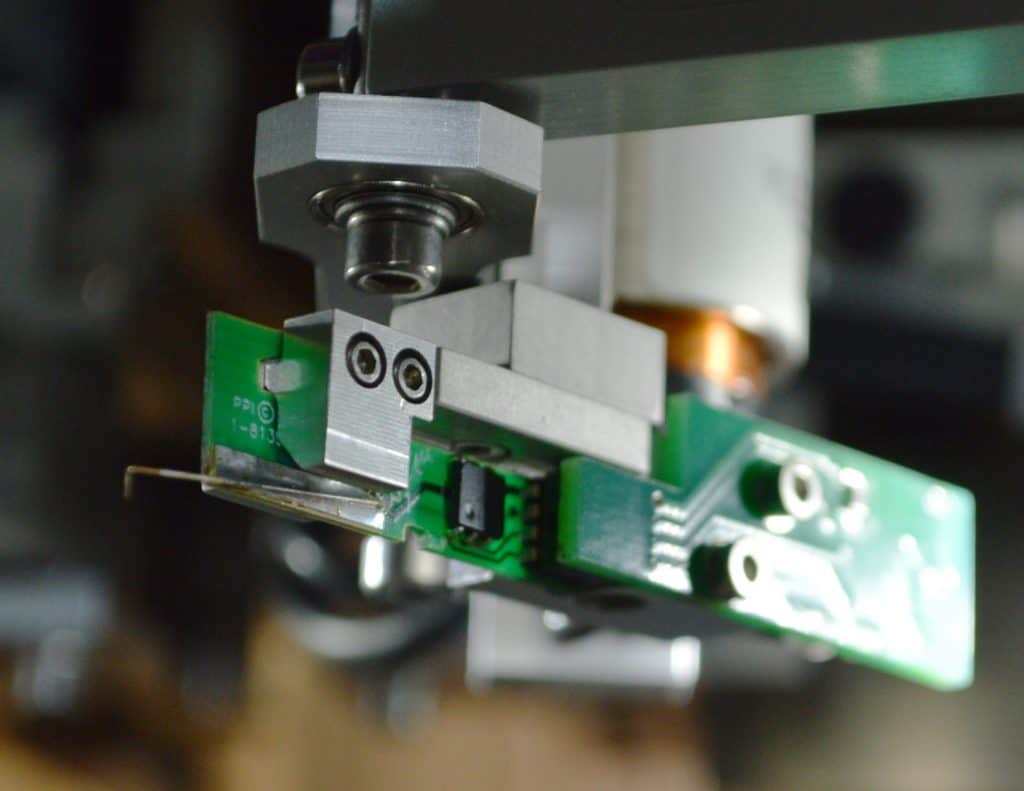

Laser trimming has become an indispensable tool for the production of microelectronic devices when high precision and performance are necessary. As portable consumer electronics evolve, the need for increased performance and reduced package sizes is pushing trimming solution manufacturers to ensure systems can meet these requirements. The as-printed tolerance distribution of resistors is typically between 10 to 20 percent, which is not adequate for most portable consumer electronics products.

PPI’s RapiTrim laser resistor trimming systems provide the optimal combination of high throughput, reliable performance and the lowest operating cost in the industry to meet the cost-sensitive demands of the consumer market.