iNDUSTRIES

Medical Devices

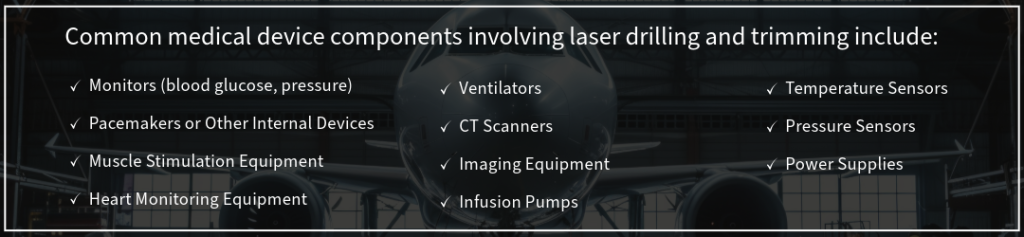

Precision, accuracy and repeatability are critical in medical devices, components often undergo laser trimming and drilling to meet these requirements.

Precision, accuracy and repeatability are critical in medical devices, components often undergo laser trimming and drilling to meet these requirements.

Printed circuit boards to support complex controllers and sensors have become commonplace in the medical field. With advances in technology, medical diagnostics, research and treatment methods have become computerized, making high density PCBs and intelligent sensors for medical equipment a standard requirement. With non-standard sizes and shapes of instruments and portable sensors as well as a need to keep sizes very small, many medical devices employ flex or rigid-flex HDI PCBs, packing a lot of connections into a small area.

Many medical devices require multiple sensors and calibration of circuit output parameters to ensure accuracy and repeatability are achieved. With active trimming, the circuit is functioning during the trim process and issues of individual component tolerance stackup is avoided. In cases where the devices are subject to specific pressures, temperatures or other environments, the trimming process may be combined with calibration and testing to that environment.

PPI’s turnkey RapiTrim systems deliver out-of-the-box solutions for sensor manufacturers, with available test data input/output interfaces and specialized device fixturing.

High density interconnect PCBs are commonly used in the medical device industry to reduce the size of devices. Multilayer boards typically employ blind and buried vias to connect layers and ensure an ever increasing number of components will fit. High density interconnect (HDI) improves overall assembly reliability which is critical for medical device manufacturers. This combined with high-resolution, accuracy, speed and flexibility makes laser processing ideal for the medical device industry.

PPI’s ProVia laser drilling systems incorporate continuous self-calibration and monitoring to deliver reliable signal interconnect and flex circuit features via-after-via and cut-after-cut, ideally suited to the stringent demands of the medical industry.